TLT-Turbo GmbH Continues to Show Resilience Through COVID-19 Pandemic

Following the first official response statement on the global coronavirus pandemic, TLT-Turbo has continued to prove operational resilience in its operations across the globe. This is largely due to the efforts of the TLT-Turbo global team and the implementation of various innovative measures including remote service support and virtual model acceptance testing. These factors have allowed TLT-Turbo to continue providing the high level of service that their clients have come to expect – with some formally showing their appreciation for the ways in which TLT-Turbo’s support has contributed to their operational continuity.

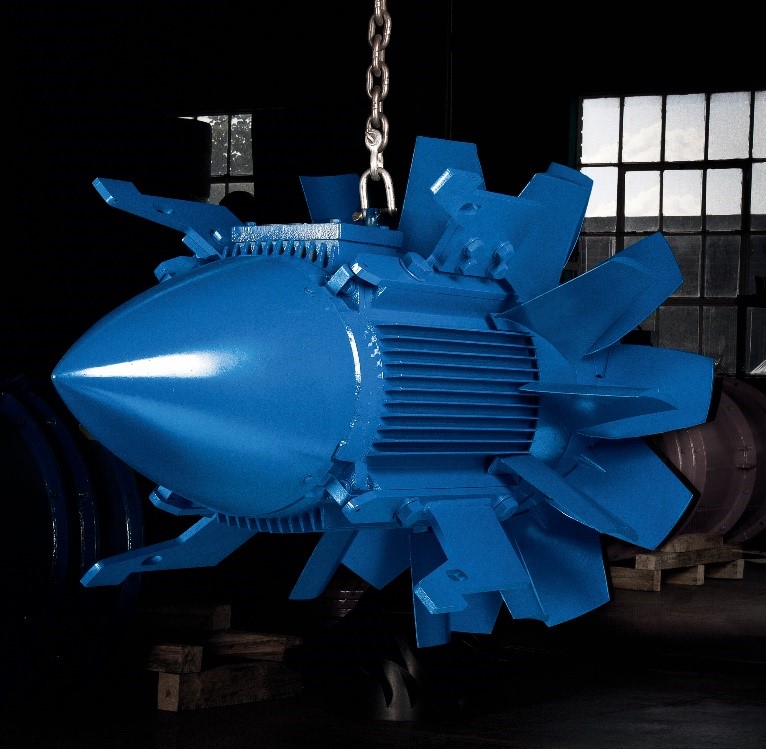

In the three months since TLT-Turbo released their initial COVID-19 response statement, they have announced several new contracts for high profile clients across the globe. Most notably this includes the supply of Sinter fans and two CDQ fans for various clients in China and an order for low flow MVR fans to a client in Colombia.

TLT-Turbo, Global Co-Managing Director, Rainer Redinger: “We knew that to a large extent our resilience in the face of such a significant global challenge would stem from the expertise and commitment of the TLT-Turbo global team. Securing of these orders demonstrates the perseverance of the sales representatives and engineers involved and speaks to the reliability of our products on the market. These same factors will ensure that we endure through the COVID-19 pandemic and current global market downturns and emerge stronger than ever.”

Travel restrictions imposed around the globe, posed a challenge to the delivery of

TLT-Turbo services and fans. TLT-Turbo implemented Remote Service Support that facilitates remote service, maintenance, repairs and troubleshooting. Using an audio-visual connection that allows the exchange of images and data between TLT-Turbo experts and customers, TLT-Turbo’s team can guide customers through the process of making simple repairs and adjustments in real time.

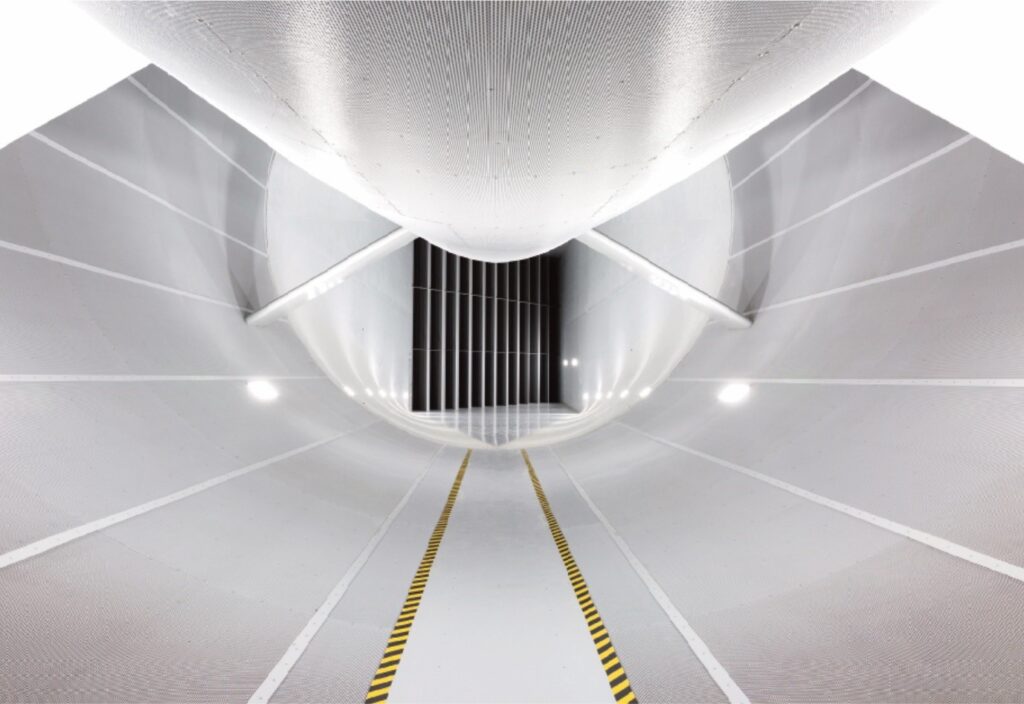

Along with this, to facilitate the delivery and commissioning of new fans, TLT-Turbo’s R&D team have also rolled out Virtual Model Acceptance Testing. TLT-Turbo made aerodynamic model acceptance measurements and final acceptance testing available for customers to attend virtually. They are now done through software that combines video conferences with a connection to virtual reality on smartphones, tablets, smart glasses or a video screen.

“This is a major advancement in the digitalization of our offering. In future, even as we move into a post-COVID world, these platforms will remain an alternative option to conventional model acceptance testing, trouble shooting, repairs, inspections and many other services for all customers as it saves them both time and money,” Mr. Redinger explains.

These efforts add to the crucial support of the regional TLT-Turbo offices across the globe that are starting to re-opening following various national lockdowns.

TLT-Turbo Africa has been operational through the continuing national lockdown in South Africa that was instituted on 26 March 2020. They have been registered as an essential service which allows for manufacturing activities with 30% of their usual staff complement per shift. “We are currently on a two-shift system of six hours per shift for operational staff. Even with limited staff, we have managed to make key deliveries to our customers,” says TLT-Turbo Managing Director, Christo Gelderblom who goes to explain that strict hygiene and safety protocols are being adhered to and that non-essential staff are still working from home. “We have received a number of orders since we returned to work and are expecting a few more in the weeks to come as South Africa’s lockdown alert levels are being lowered.”

In Korea, TLT-Turbo representatives have been able to recommence visits and meetings at client sites while adhering to strict hygiene, prevention and social distancing measures. The regional office has reported that they are almost back to business as usual while taking every measure to protect the health and safety of their staff. Their manufacturing facility continues to be fully operational.

Currently, TLT-Turbo manufacturing facilities in the USA, Germany and China are also operational. TLT-Turbo Global Co-Managing Director, Xiongfei Zhao: “We have done everything in our power to keep our processes running as smoothly as possible. We have complied with all required hygiene regulations and have developed our own additional safety measures to ensure that our staff are taken care of. We have also ensured that our customers are able to reach us by making our team accessible on electronic platforms as they continue to work from home.”

This accessibility has allowed TLT-Turbo’s customers to continue to rely on the products and services that play a crucial role in their daily operations. Several customers have sent in words of gratitude for the role that TLT-Turbo’s products and support have played in keeping them going.

Currently, TLT-Turbo continues to encourage concerned clients and suppliers to reach out their TLT-Turbo representatives in the various regions. Locate your nearest point of contact here.