Advanced Ventilation Solutions: A Major Mine

Industry leader in mining

One of the world's largest gold mining companies by market capitalization operates in several countries, including Canada, Australia, Finland, Mexico, the United States and Colombia. Its commitment to safety and efficiency is evident at one of its key mines in Quebec, where significant advances in deep mine ventilation have been made.

Project overview

The Quebec mine, one of the company's main operations, needed to upgrade its ventilation system due to its extreme depth of 2,750 meters. The goal of the project was to improve safety and operational efficiency as part of the mine's expansion. TLT-Turbo, specifically TLT-Turbo North America, has had a longstanding partnership with the mining company for over 25 years and has already supplied two main surface fans as well as large underground booster fans, all with in-service blade adjustment.

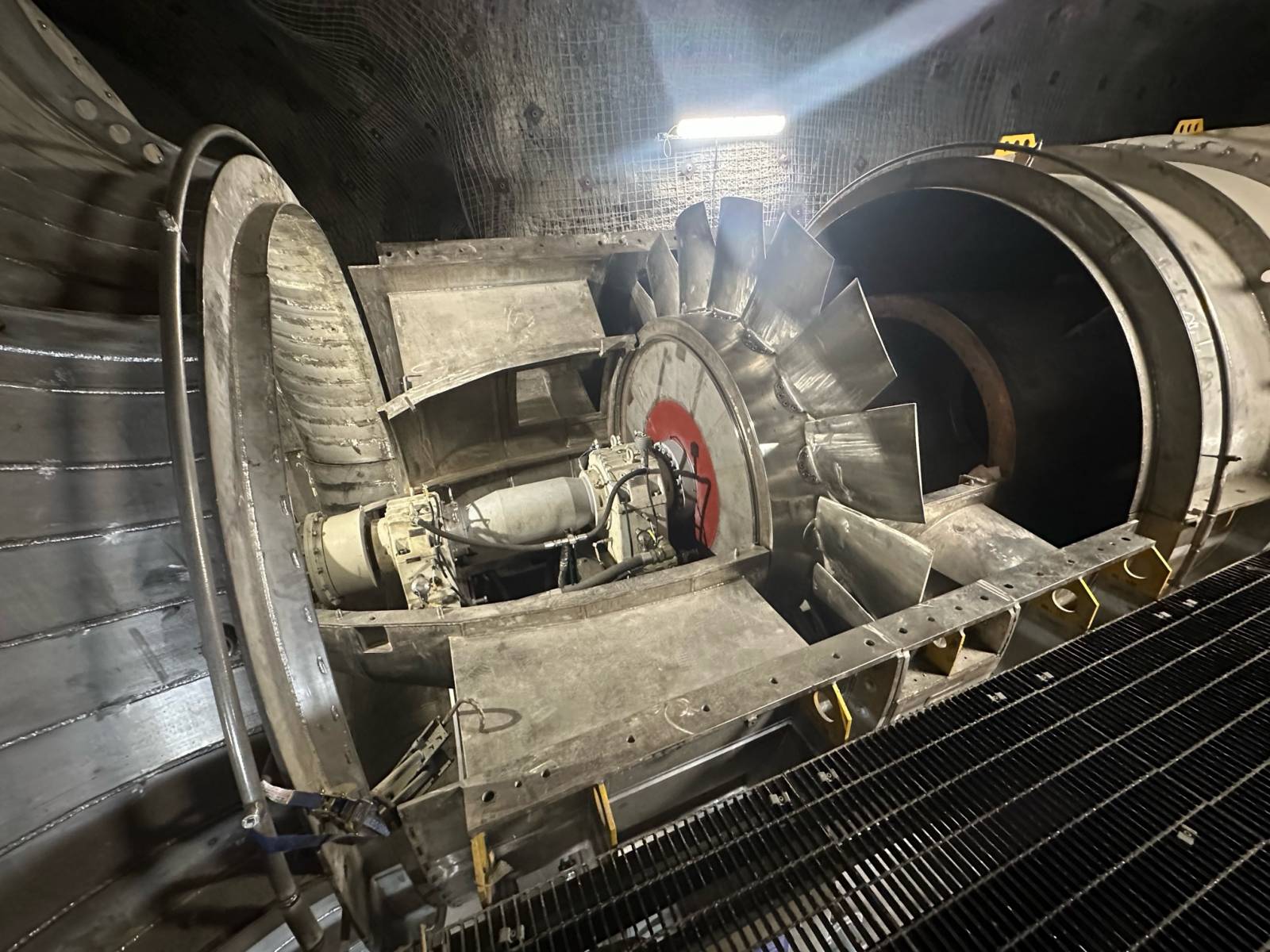

Challenges and innovations

The biggest challenge was the mine's harsh environment with high humidity and low pH, which can cause rapid deterioration of equipment. To combat this, the company installed two high-efficiency stainless steel axial fans with duplex blades, specifically selected for their corrosion resistance.

Results and conclusion

This highly acidic environment provided TLT-Turbo with the opportunity to develop a stainless steel solution to increase fan life and reduce maintenance and operating costs. The upgrade provided the Quebec mine with a robust and efficient ventilation system that can withstand the harsh conditions and support the mine's long-term goals. The project underscores the company's proactive approach to using innovative technologies and strengthens its position as a leader in sustainable mining practices.

The successful improvement of the ventilation system at the Quebec mine reflects the company's commitment to excellence and its strategic partnership with TLT-Turbo. This partnership is setting new industry standards for operational efficiency and safety in extreme environments.

Solution implementation

- 2x GAF 31 5/20-1 axial fans, designed for blade adjustment during operation.

- Operating data: 316 m³/s, 7,800 Pa, 890 rpm, 2,800 kW.

- Application: Extraction of the main mine fan underground to improve mine ventilation.

- Construction: Duplex stainless steel impeller and blades, 316L stainless steel transition piece, inlet nozzle, guard screen, deflector corner and diffuser. Additional Components: Weather vanes, lubrication and hydraulic control system, and holding brake.

- Control System: Extensive instrumentation and monitoring.

- Structural Integration: Expansion joints with full installation service.