Long lasting equipment is a must have for many industries due to the cost savings that can be derived from a longer lifespan on equipment and components. At their recently upgraded testing facility, TLT-Turbo GmbH are using a new research methodology based on dust particulate samples from steel manufacturing and processing facilities to determine the best solutions for minimizing wear on ventilation equipment based on the unique abrasive factors of this specific operating environment.

TLT Turbo GmbH is one of the world’s leading suppliers of heavy-duty centrifugal fans designed to operate efficiently in the most challenging applications. In the steel industry, these fans are exposed to high dust loads which causes them to prematurely fail due to faster wear. To determine the best solutions for slowing wear and tear, TLT-Turbo researchers procured original samples of the dust present at customer facilities and used these to investigate the reasons for wear and to determine remedies for reducing it.

Factors Affecting Wear on Fans

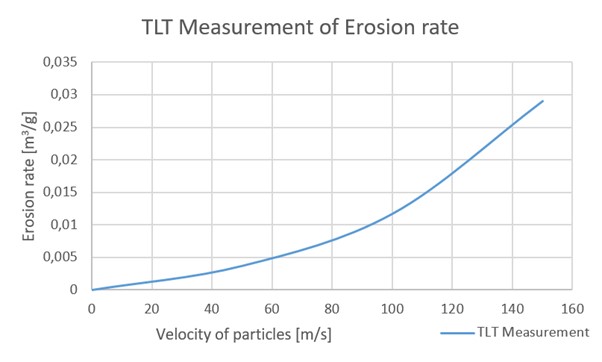

According to Sabine Groh, Product Manager for industry fans at TLT-Turbo in Bad Hersfeld, Germany, the main contributing factor to wear is the velocity of the abrasive particle. The erosion rate measurement below illustrates the exponential increase in the erosion rate based on velocity.

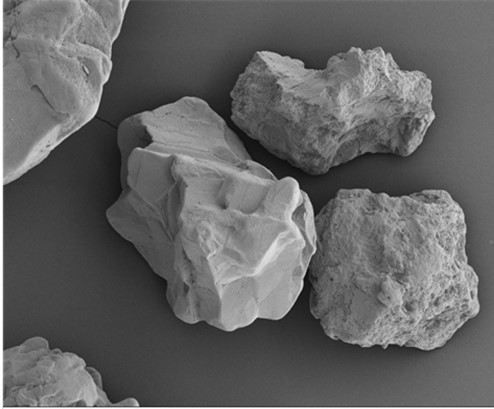

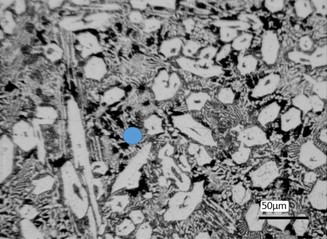

Groh states that additional factors include hardness, shape, number of particles and the angle between the particle jet and the surface of the fan component. The image below provides an indication of the typical shape of the abrasive particles used for research at TLT-Turbo’s newly upgraded particle jet test stand in Zweibrücken.

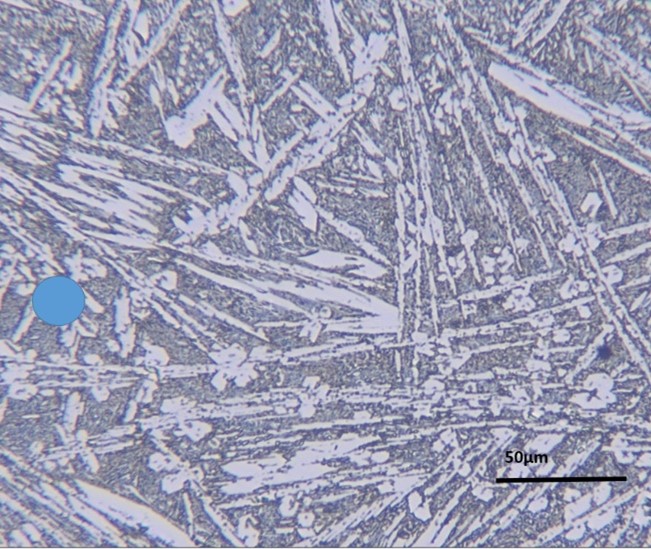

Finally, Groh argues that the particle size in comparison to the size and distribution of grain of the coating also plays a role. Figure 3 below shows a micrograph of a hardfacing layer suitable for abrasive dust with small particle sizes using a prototypical particle of 20µm. Figure 4 below shows a micrograph of a common Chrome Carbide hardfacing with a prototypical particle of 20µm as well. “In Figure 3 we can observe that the particle is less able to wash out the matrix because of the more homogenous distribution of the smaller grains. Figure 4 however shows that the large grain size and large distribution allows for easier erosion of the matrix,” Groh explains.

special Hardfacing optimized for small abrasive

This proves that if the abrasive particles are small enough to impinge between the relatively hard grains of a hardfacing, then the matrix will be washed away and the grains will easily fall out afterwards. If the grains of the hardfacing are small enough with less space between them, matrix erosion will be prevented and the hardfacing will have a higher durability.

Emerging Research Trends

Over the last 10 years, TLT-Turbo performed thousands of particle jet tests to determine the erosion rate of different coatings and materials. To achieve a comparison between these coatings, a standardized test sand with a specific grain size distribution was utilized as abrasive material (as illustrated in Figure 2 above).

“TLT-Turbo has developed an extensive database on the erosion rates of different coatings and materials that have been exposed to the test sand at different angles and velocities. This database allows us to select promising solutions for customer’s abrasive problems,” says Groh.

TLT-Turbo has recently upgraded its test equipment and now has the capability to test using original dust supplied by the customer. Groh explains that this allows for the specific customer application, with all major influencing factors to be reproduced. In addition to the velocity and angle of the abrasive dust, a realistic indication of particle size, shape and hardness can now contribute to more accurate test results. “This means that we can provide a more definitive prediction of how a change in wear protection will affect the service lifespan of the equipment to each customer.”

Wear Test Case

The TLT-Turbo test lab asked a European customer to provide samples of dust from their facility for testing to determine how they could benefit from a coating solution suited to their specific application and environmental challenges.

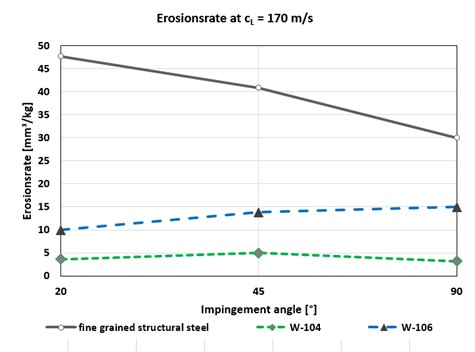

From this specific dust particle sample, the grain size distribution was determined by performing a sieve analysis. Particle jet experiments were then performed on two preselected coatings. These experiments are in accordance with the norm DIN 50332 and were executed for three angles: 20°, 45° and 90°.

Figure 6 below illustrates the test results. The TLT W-104 coating was determined to be the best alternative for all impact angles, however the superiority of W-104 is best illustrated when used for the 90° impact angle.

In extremely abrasive applications, the choice of wear protection determines the service life of the fan. The upgraded test lab and particle jet test stand has afforded TLT-Turbo engineers a deeper understanding of the mechanisms behind wear and the effects of specialized solutions. This has led to new approaches in product advancement and development that are grounded in providing solutions that meet market requirements.

“The ability to use the original dust from the customer’s facility and duplicate the conditions such as velocity and the impingement angle on the coating, allows us to determine how all these factors including the shape, size and hardness of the abrasive particles affect erosion rates. TLT-Turbo has taken another great step forward in being able to reliably calculate the effect that changing in coatings to prevent wear will have on extending the service life of ventilation equipment. Establishing the best solution for wear related challenges now becomes a collaboration between TLT-Turbo and the customer.” Groh concludes.