Anuga FoodTec 2022

Anuga FoodTec 2022 showed that there is a great need for energy savings on the part of the industry – especially in the area of evaporation technology. A great potential lies in the saving of steam generation costs.

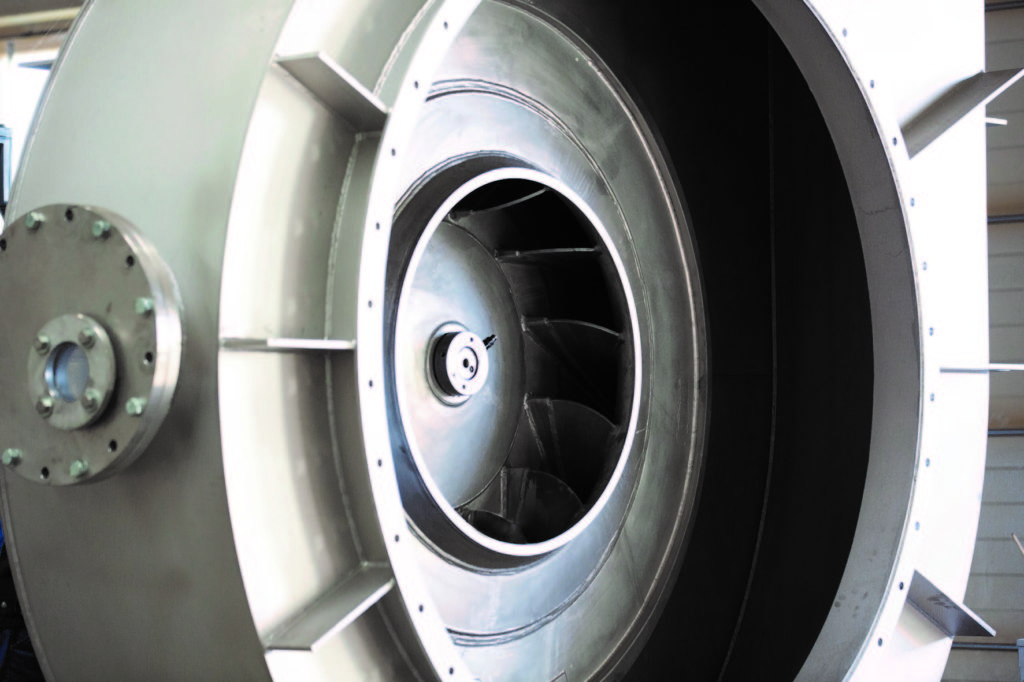

With focus on energy and cost efficiencies in the food and beverage industry that were the center of attention at Anuga FoodTec (AFT) 2022, the use of mechanical vapor recompression (MVR) was identified as a central key to reducing energy requirements for steam supply in plants.

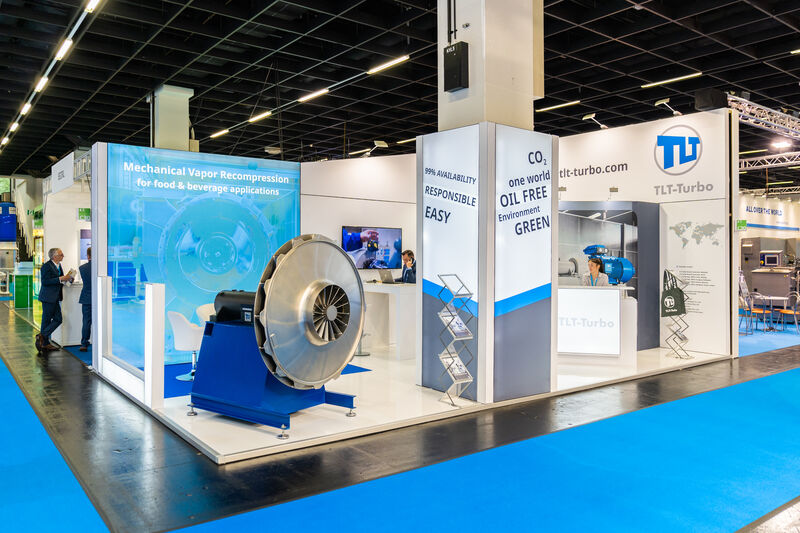

Global ventilation fans and systems manufacturer, TLT-Turbo GmbH, concluded its participation at the 2022 Anuga FoodTec tradeshow, which took place from April 26-29 at Cologne, Germany. As the world’s most prominent food and beverage industry tradeshow, the event showcased a mix of physical and digital offerings to the industry covering a wide variety of new concepts and solutions for meeting the challenges facing food and beverage producers worldwide.

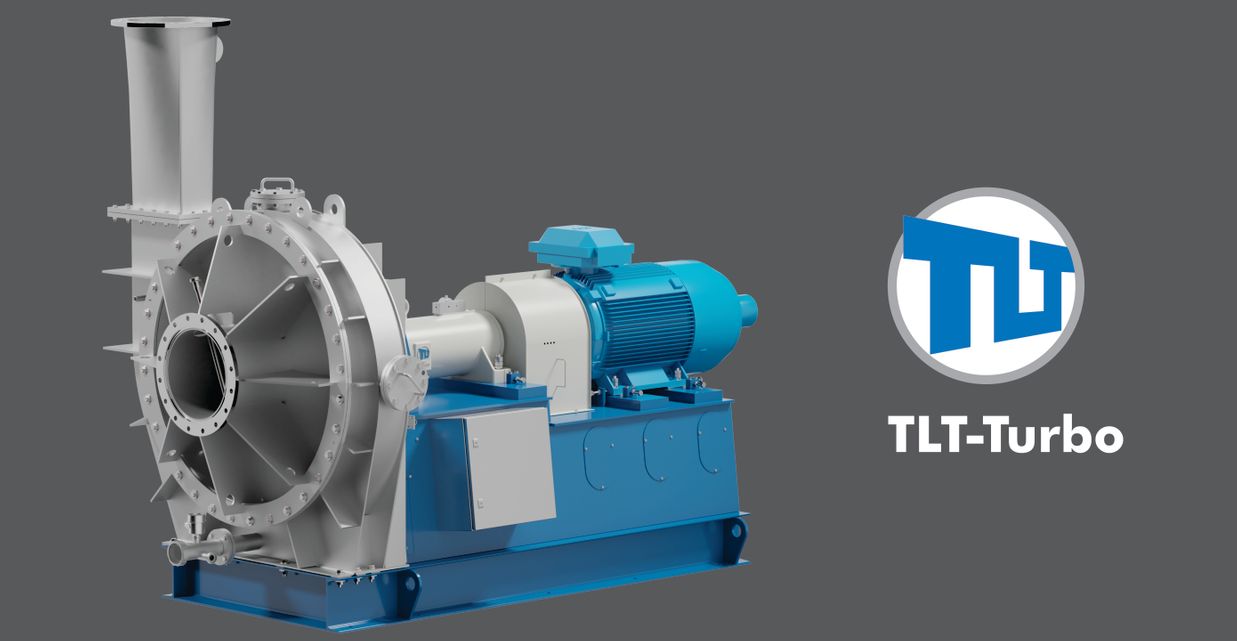

With increasing requirements and legislation regarding energy savings and avoidance of CO2 emissions set to affect these industries in the next few years, the introduction of energy-efficient technologies and equipment is critical to sustained success. Mario Schmidt, TLT-Turbo Head of the Vapor Fans Business Segment, says that TLT-Turbo participated at AFT for exactly this reason. “We offer high efficiency fans, which are used primarily in the food, beverage and pharmaceutical industries, among many other applications. These fans can help our customers to modernize and upgrade existing plants or to provide vapor processing for new production lines. Furthermore, they help to achieve CO2 footprint reduction and minimize the use of fossil fuels in vapor production,” Schmidt explains.

TLT-Turbo products, renowned for their energy efficiency capabilities, are a perfect fit for food producers who want to increase their energy efficiency, increase their availability and minimize their maintenance costs. “We have now expanded our product portfolio to the point where we can serve the widest possible range of mass flows at considerable pressure increases, in order to offer customers the greatest possible flexibility in their plant design” explains Schmidt.

“AFT 2022 provided an opportunity for us to connect with customers for the first time in a while. We had quite a number of visitors to our booth who were interested in what our MVR range has to offer and I am glad to say that many leads and potential projects arose from these conversations”, says Schmidt. “Visitors included both potential new customers and existing customers who we had invited to our booth. The trade show gave us the opportunity to have constructive discussions with our customers and discover new potential. We look forward to building on this at further trade shows. It was a great reminder of how manufacturers and customers can inspire and learn from each other.”

Schmidt emphasizes that TLT-Turbo’s presence at the event, and particularly the focus that they placed on the MVR range this year, was very important. This enabled the TLT-Turbo team to interact more closely with customers and discuss new innovative solutions for the future.

“I am pleased that our customers were quick to recognize that our product addresses the needs for minimizing maintenance costs and ease of implementation of the product in the customer’s plant, in addition to the tremendous energy savings. A key to this is the proven ceramic hybrid bearing, which is used in all TLT-Turbo MVR fans.”