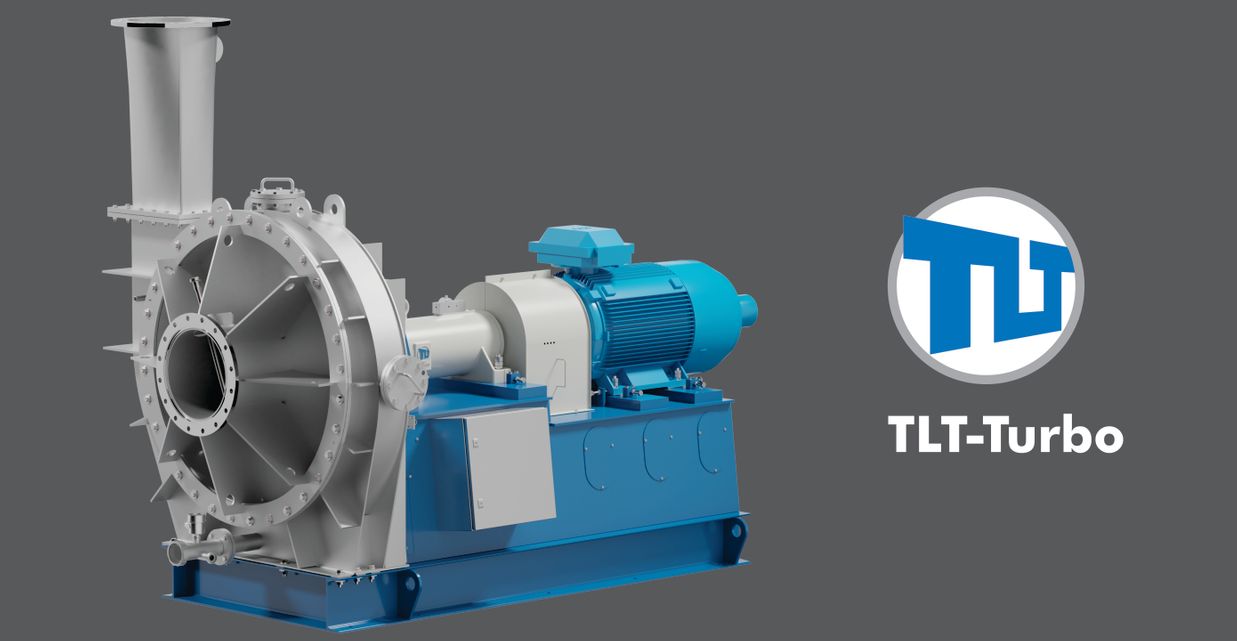

TLT-Turbo consolidates its position as an MVR expert in serving the pharmaceutical industry

In October 2021, after TLT-Turbo received a huge new order for 20 MVR fans, another additional order for 4 larger MVR fans was put in by the same customer. This order precedes the delivery of 32 machines to the customer which shows its satisfaction in our products and continued trust in TLT-Turbo.

Four years ago, TLT-Turbo was a newcomer to the MVR industry and completely unknown to potential customers, especially those in the pharmaceutical industry. “Within four years we have strived to make considerable ground in the market by supplying numerous high-quality MVR fans of various sizes”, says Mario Schmidt, Head of Business Segment Vapor Fans.

After intensive and positive discussions and a huge effort by our TLT-Turbo team in Beijing, we successfully wrapped up two orders in a row from our main client in the pharmaceutical industry. TLT-Turbo ensures to provide continuous delivery of 3 to 4 fans every 6 weeks up to September 2022. This continued partnership shows the confidence and trust that the customer has in TLT-Turbo. This new order also strengthens TLT-Turbo’s market position as MVR experts serving the pharmaceutical industry which will help grow our customer base further in 2022.

“Our MVR range is ideally suited to facilities in the pharmaceutical industry as witnessed by our continued partnership with our customer who uses our fans in the process of manufacturing Water For Injections (WFI),” says Mario Schmidt, Head of Business Segment Vapor Fans. He further added that, “given the higher efficiency of TLT-Turbo manufactured MVR fans, it makes us more competitive in the small to medium mass flows market where there are many potential clients in different industries such as dairy, food and beverage and pharmaceutical production.

For more information on the TLT-Turbo MVR range, click here.